FAQ - Package Boiler

- What kind of boilers are available as KTE’s lineup?

- We offer Once-through boiler, Water tube boiler, Fire (smoke) tube boiler, and Heat Recovery Steam Generator (HRSG). For more information, please see this page.

- What are the characteristics and advantages of each type of boiler?

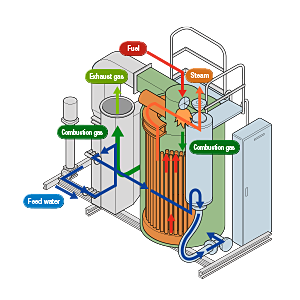

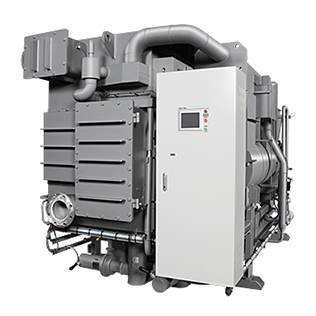

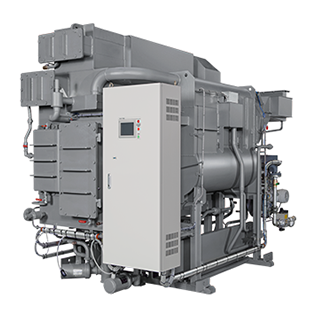

- Once-through boiler is one of Water tube boilers composed of water tubes and there are single-tube types and multi-tube types. We manufacture multi-tube type Once-through boiler, with high efficiency and compact size.

Water tube boiler has a structure which upper steam drum and lower water drum are connected by many tubes. Steam is generated by combustion gas to heat water tubes. Boiler can generate a large amount of steam at high pressure and it also supports special options such as super heater.

Fire (smoke) tube boiler has a cylindrical structure. Boiler body is filled with water and a smoke tube where combustion gas passes runs through the body. The heat of combustion gas heats water and generates steam. Compared to Water tube boiler and Once-through boiler, Fire (smoke) tube boiler holds a large amount of water, therefore it is able to match fluctuating steam load.

Heat Recovery Steam Generator (HRSG) uses heat of exhaust gas to generate steam. HRSG is built in co-generation system to utilize exhaust gas from gas turbine and gas engine. For more information, please see this page. - Is hot water boiler available in KTE’s lineup?

- We do not supply hot water boilers. However, we can offer various types of steam boilers. For more information, please see this page.

- What types of fuel can I use for boilers?

- Natural gas, LPG, and Diesel oil are the main fuel for our boilers. Depending on model, other types of fuel can also be used. For more information, please see this page, or contact KTE for further details.

- Can I operate KTE's boilers easily?

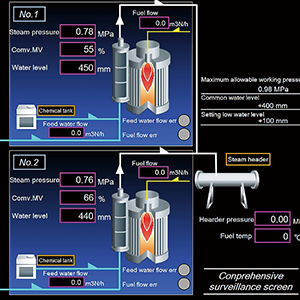

- You can start and stop boilers simply by pressing a single button on control panel.

For Once-through boiler, all operations can be done on easy-to see LCD monitor. LCD monitor displays the operating status and error messages, and also you can easily confirm operation status such as standby, operating, notification, and error by LED light. - How long does it take until a boiler can supply steam?

- It depends on capacity, but in general, it takes about 40 minutes for Water tube boiler, about 1 hour for Fire (smoke) tube boiler, and about 5 to 10 minutes for Once-through boiler, to start supplying steam from cold start.

- How long is life time of KTE's boilers?

- It depends on such as model, the quality of raw water supplied to boiler, and condition of boiler water treatment.

If maintenance is appropriately done, generally, 30 years or more for Water tube boiler and Fire (smoke) tube boiler, and 8 to 10 years for Once-through boiler.

KTE's Once-through boiler is designed to be used for more than 15 years. Please feel free to contact KTE for further details. - Where are KTE's boilers manufactured?

- KTE's boilers are manufactured at our plant in Japan, including material processing, welding, annealing and assembly. We also have a showroom where you can see the actual operation of boilers. For more information, please see this page.

- How can I purchase KTE's boilers?

- KTE's boilers are available to be purchased from our distributors. For a distributor in your country, please see this page.

- How can I purchase maintenance parts for KTE's boilers?

- Maintenance parts can be purchased from our distributors. For a distributor in your country, please see this page.

- How much is KTE's boiler price?

- Prices will vary depending on such as the pressure, steam amount, or fuel type, for each customer’s case.

We will provide quotation to meet your request. Please feel free to contact KTE for further details. - How long does it take to have KTE's boiler delivered?

- Delivery time will vary depending on such as the pressure, steam amount, or fuel type, for each customer’s case.

We will provide quotation to meet your request. Please feel free to contact KTE for further details. - How can I get maintenance and support for KTE's boilers?

- Our distributor will provide maintenance and support. For a distributor in your country, please see this page.

- What is PID combustion control?

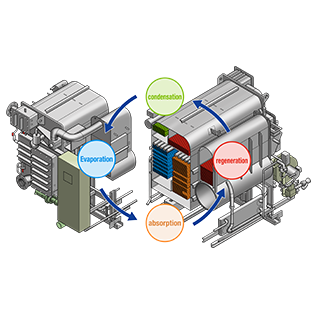

- PID control combines Proportional control (P) for controlling the combustion amount in proportion to pressure, and Integral control (I) and Derivative control (D) for maintaining steam pressure. PID control makes it possible to supply steam in accordance with steam load. Also, it optimally maintains stable steam pressure and high boiler efficiency.

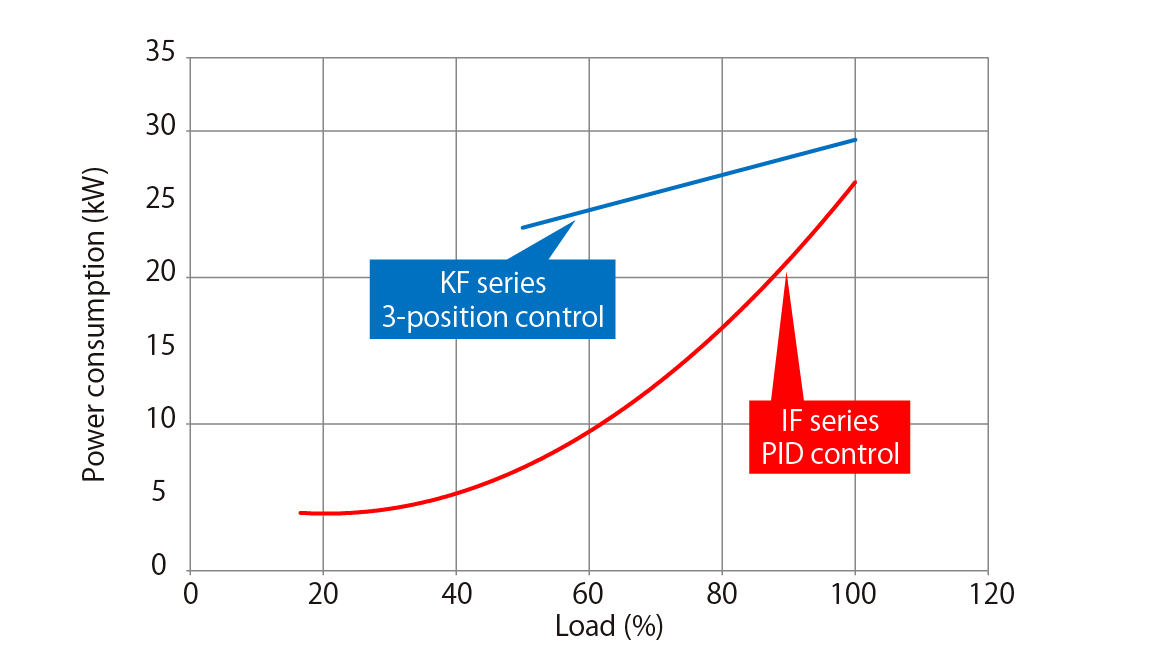

- Which functions make it possible to reduce electricity cost?

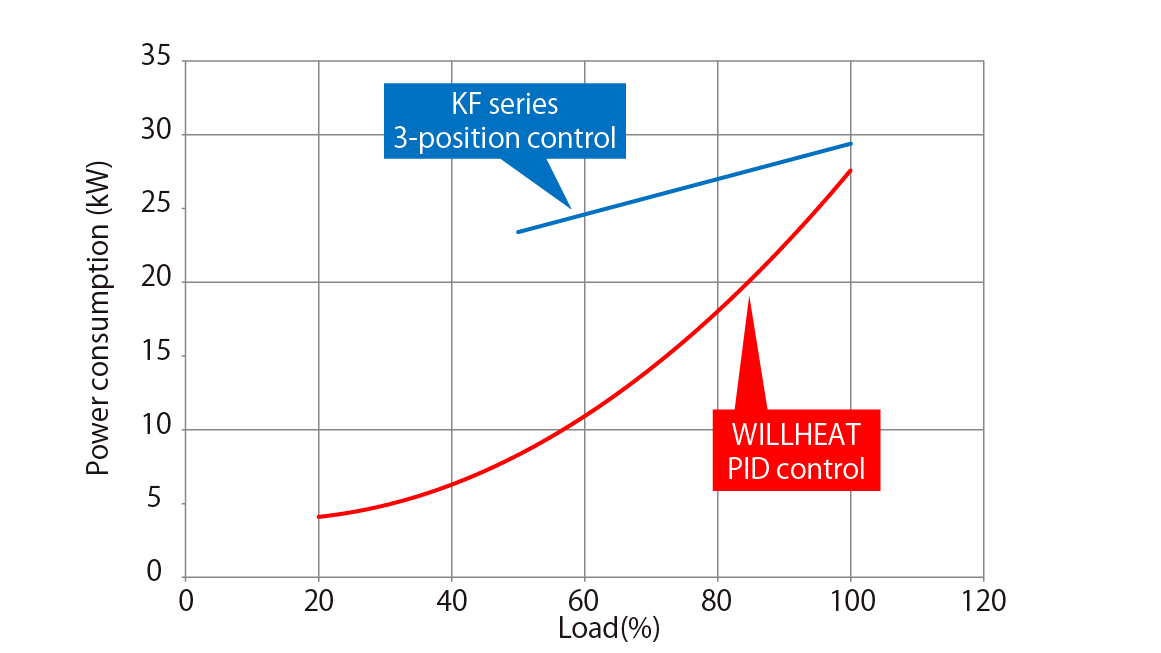

- The inverter that controls forced draft fan and feed water pump helps to reduce electricity cost.

Even when boiler is operating at low load, inverter suppresses motor output and significantly reduces power consumption.

- How is 99% efficiency achieved?

- Stainless steel economizer which includes a newly-developed high-performance heat exchanger tube significantly contribute to high efficiency.

Also, we apply PID control (a combination of Proportional control (P) for controlling the combustion amount in proportion to pressure, and Integral control (I) and Derivative control (D) for maintaining steam pressure) for controlling combustion and feed water, and it enables to supply steam in accordance with the steam demand and achieve high efficiency. - How many boilers can be operated multiply in maximum?

- A maximum of 16 boilers can be operated multiply with multi-unit control.

- Why KTE boilers can supply high-quality steam?

- The following are the main reasons for high-quality steam.

(1) PID combustion control

(2) Continuous feed water control

(3) High-performance centrifugal steam water separator

(4) Water feeding to steam water separator

These functions prevent fluctuation of water level in steam water separator, steam pressure fluctuation, and sudden fluctuations in the amount and temperature of feed water. It enables to supply stable and high-quality steam.Structure of steam water separator

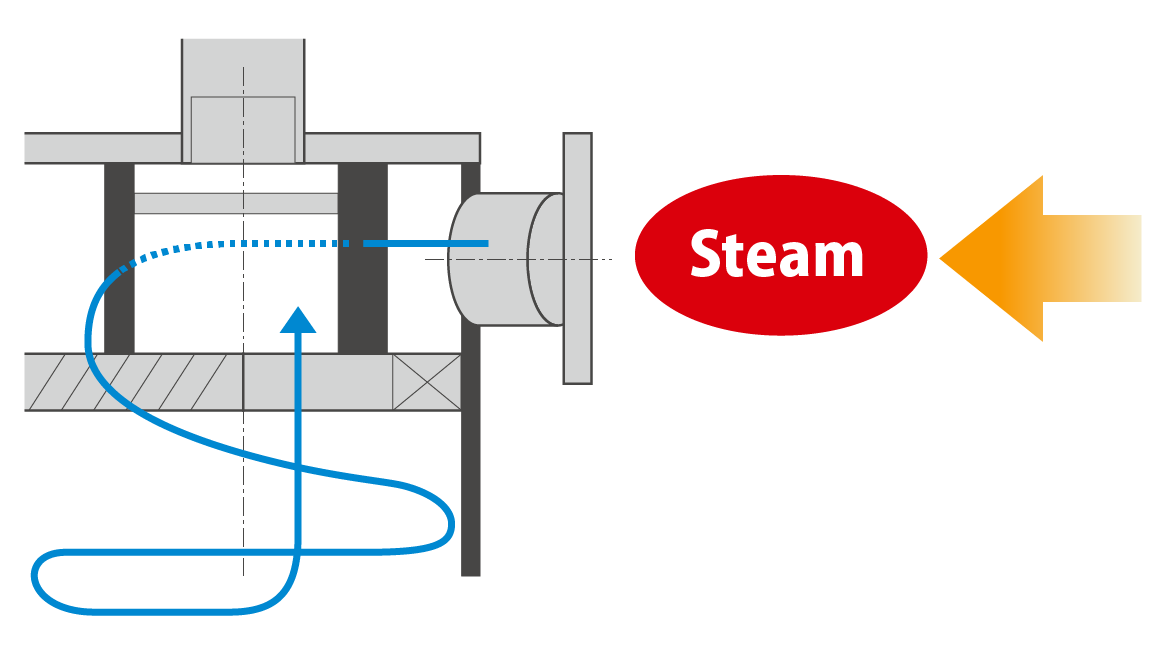

Centrifugal rotation is additionally applied to commonly used reversing type of steam water separator so that steam dryness has highly improved.

Water feeding to steam water separator

- What kind of technology is used to achieve high durability?

- The following are technologies and manufacturing methods to achieve high durability.

(1) PID combustion control prevent heat stress and thermal fatigue breakdown.

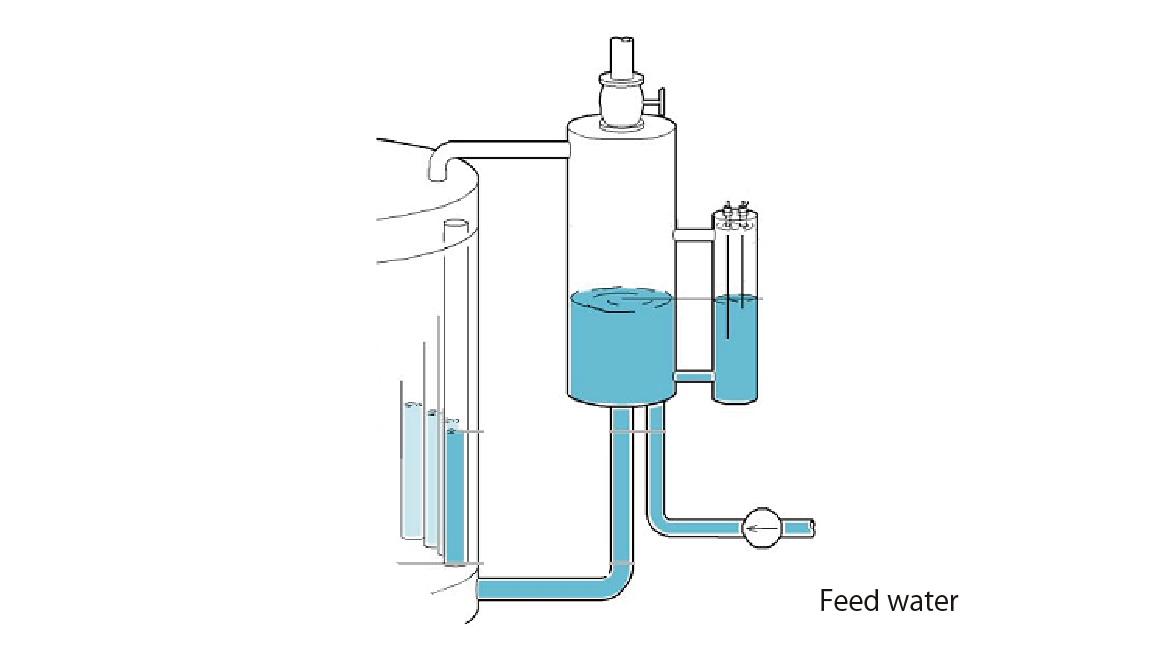

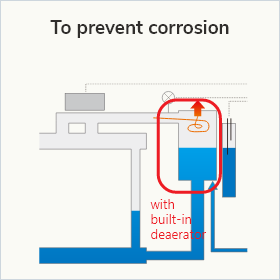

(2) Our process to supply feed water to steam water separator with a built-in deaerator helps to reduce dissolved O2 (oxygen) in the feed water and prevents corrosion troubles.

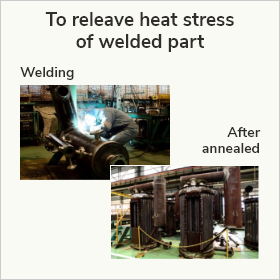

(3) We perform annealing process in manufacturing process to remove heat stress generated by welding, which reduces the risk of cracking for welded parts.

(4) Round drum body structure uniformly receives radiant heat of flames and eliminates localized heating. This alleviates load on the drum body and improves durability.Round design for pressurized part

Steam water separator

with built-in deaerator

Water feeding to steam water separator

Annealing of pressurized part

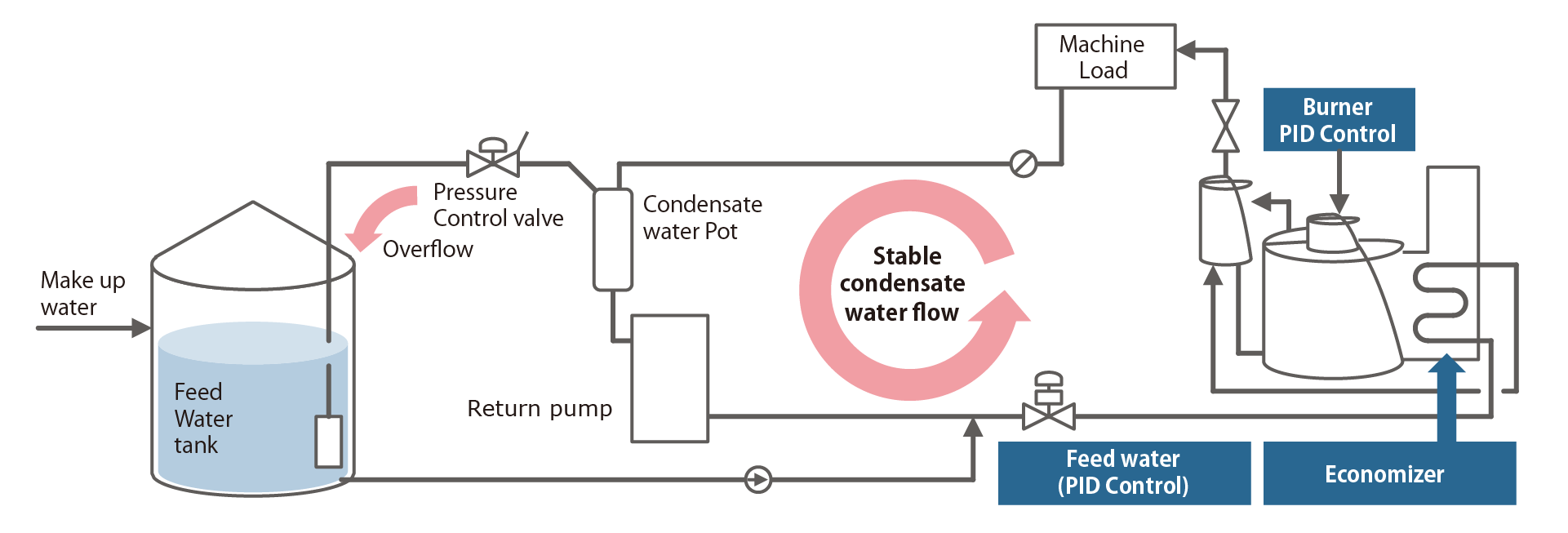

- What is closed condensate water recovery?

- Condensate water recovery is a system that recovers energy remaining in condensate water after production facility.

Condensate water discharged under pressure from production facility is transferred near to boiler without using a power source. The condensate water is then reused as high-temperature water. The system uses high controllability to preferentially supply high-temperature water to boiler.

The system efficiently utilizes total heat, motive power, and water resources without wasting and it contributes to reduce fuel consumption and CO2 emissions.

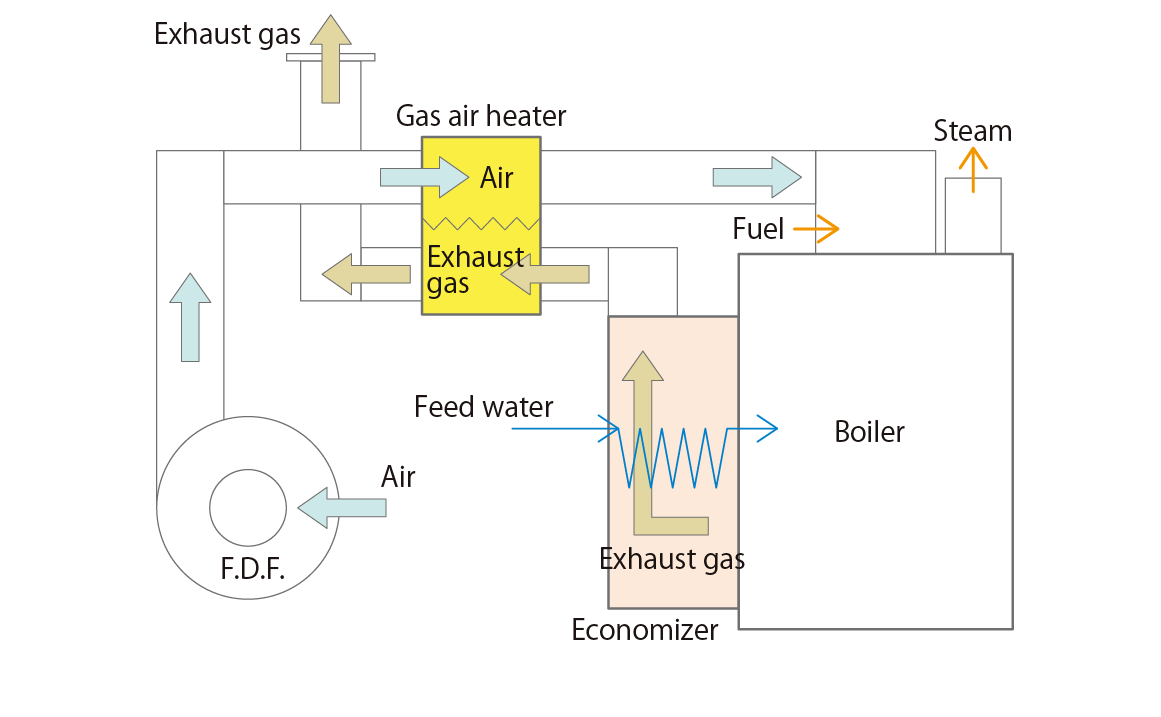

- What is gas air heater?

- It is one of energy-saving equipment that uses the retained heat of exhaust gas to pre-heat combustion air. Once-through boiler is equipped with economizer which saves energy by using retained heat of exhaust gas to pre-heat feed water. However, in the case of high-temperature feed water, the range of temperature rise for feed water becomes small, and heat recovery range of the exhaust gas also becomes small, therefore the large amount of heat is released. Adding gas air heater makes it possible to recover the released heat and it enables to improve boiler efficiency, and it also contributes to reduce fuel consumption and CO2 emissions.

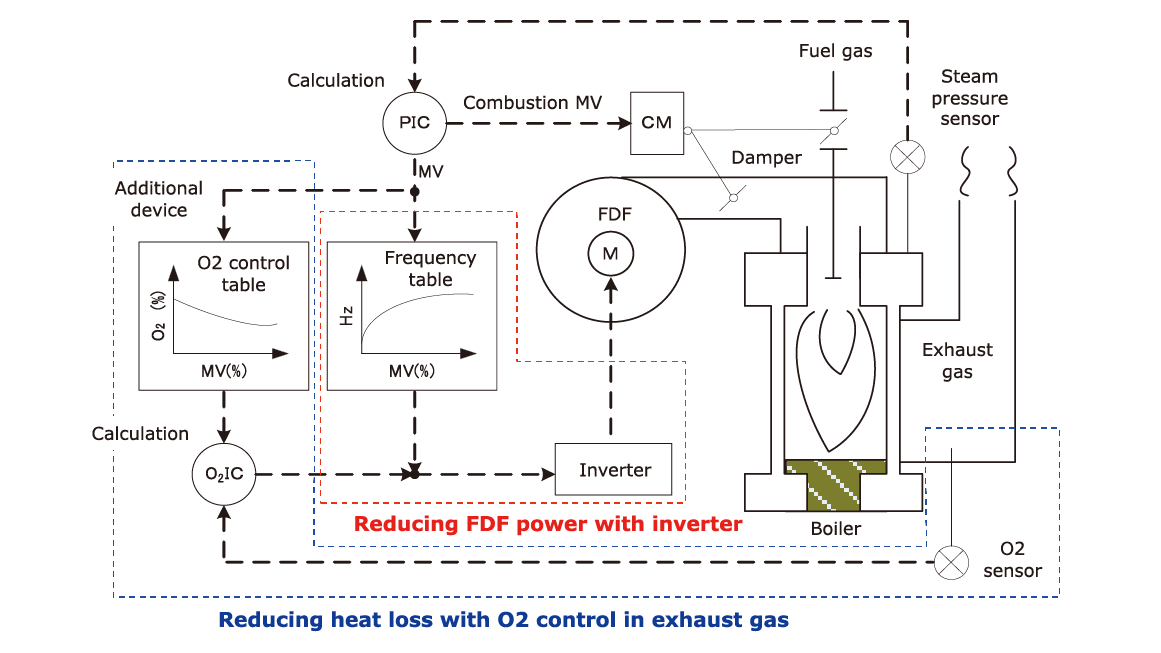

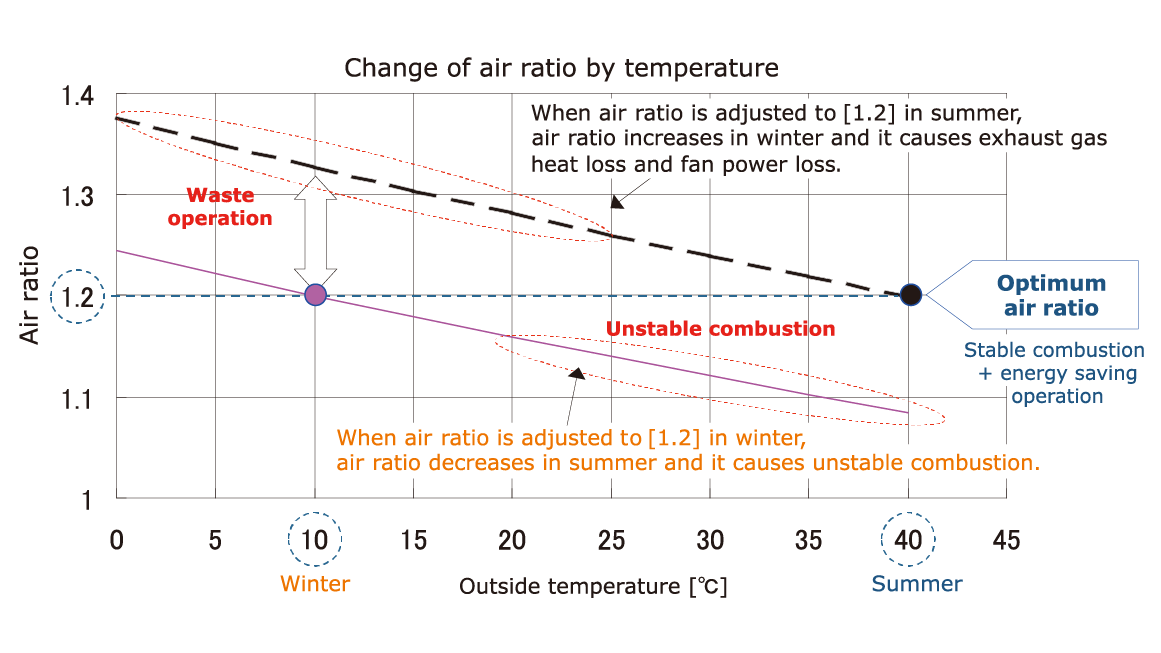

- What is O2 trimming in exhaust gas system?

- It is a function to constantly monitors O2 (oxygen) concentration in exhaust gas and controls the rotation speed of forced draft fan. This makes it possible to maintain the optimal air-fuel ratio without being affected by fluctuations in temperature, atmospheric pressure, or fuel composition. This suppresses excessive air loss and reduces fuel consumption, power consumption, and CO2 emissions.

- What is turn-down ratio (TDR)?

- TDR is the ratio of burner maximum combustion amount and minimum combustion amount. The larger the ratio, the more continuous combustion is possible in the lower load range. This significantly reduces combustion purge loss due to repeated ON-OFF of combustion. It also prevents decreased efficiency due to purge (ventilation) loss and heat dissipation loss that occur when combustion is stopped.

- What is a dual fuel?

- It is an option to switch between gas and oil for its fuel source. It helps BCP compatibility for industries which require constant steam supply, and enables installation of boilers as preparatory measures at factories in areas where gas pipelines will be laid in the future.